Primary Processing

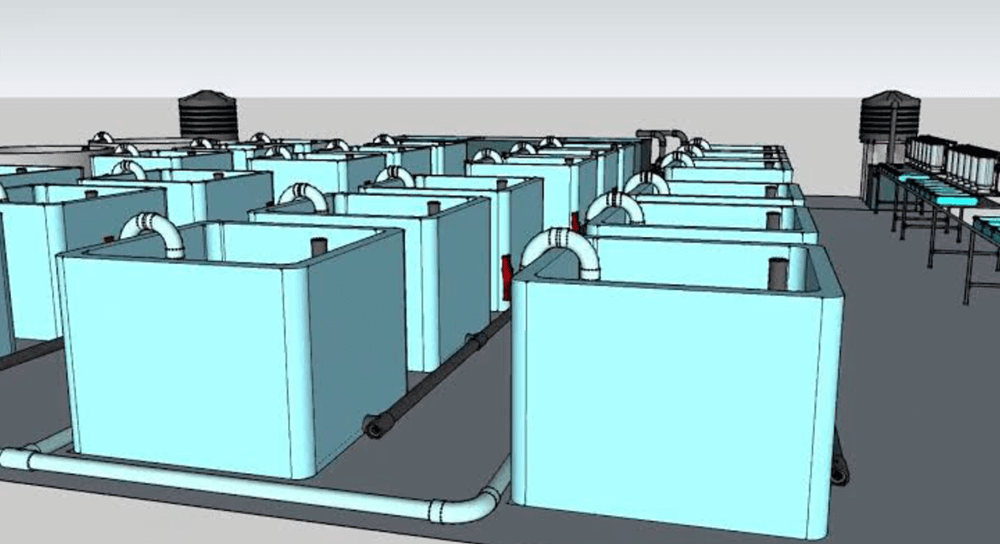

Great Lakes Tilapia’s fish processing and value – addition will be determined by market – demand and production capacity. Initial, at lower capacity of 3,300 Mt/Annum, management will execute only primary processing: Scaling and Gutting.

As capacity increases and international exports (beyond regional markets) become a reality, Filleting will be introduced. All products will be marketed as fresh or frozen, under the brand name “Fresh Harvest”.